AI tools for inventory management in vehicle repair transform operations through machine learning algorithms, predictive analytics, and automated processes. These innovations optimize spare parts tracking, demand forecasting, ordering, and stock management, leading to improved efficiency, reduced downtime, enhanced customer satisfaction, and stronger business performance for repair centers.

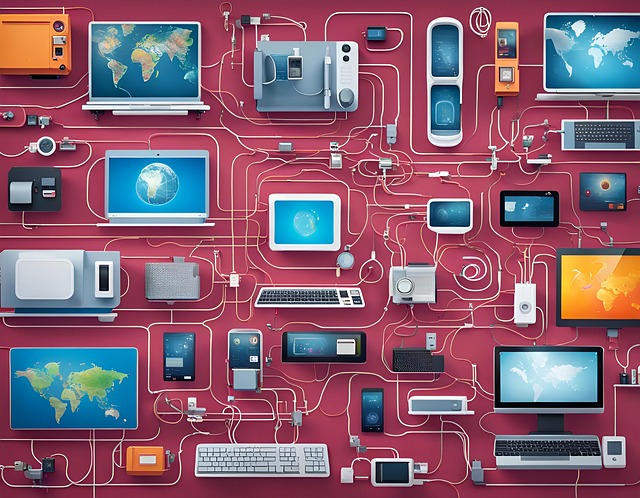

In today’s digital era, vehicle repair centers are leveraging AI tools to enhance operational efficiency. This article explores three key areas where AI is making waves: Streamlining Inventory Tracking with AI, Predictive Maintenance to reduce downtime, and Optimizing Parts Procurement Strategies. By integrating these AI-driven solutions, repair centers can improve productivity, minimize costs, and provide faster, more reliable services, ultimately gaining a competitive edge in the market.

- Streamlining Inventory Tracking with AI

- Predictive Maintenance: Reducing Downtime

- Optimizing Parts Procurement Strategies

Streamlining Inventory Tracking with AI

AI tools are transforming the way vehicle repair centers manage their inventory, offering a more efficient and accurate system than traditional methods. By leveraging machine learning algorithms, AI can streamline the tracking process by automatically identifying and categorizing spare parts as they enter the workshop, reducing manual data entry and minimizing errors.

This advanced technology enables real-time updates on stock levels, ensuring repair technicians have immediate access to precise information when needing specific components for a job. Furthermore, predictive analytics capabilities can forecast demand patterns, optimizing ordering processes and reducing the risk of shortages or overstocking.

Predictive Maintenance: Reducing Downtime

Predictive maintenance, powered by AI tools for inventory management in vehicle repair, is transforming the way vehicle repair centers operate. By analyzing vast amounts of data from sensors and historical service records, these AI tools can predict equipment failures before they occur, significantly reducing downtime. This proactive approach allows repair centers to schedule maintenance activities during less busy periods, minimizing disruptions and optimizing resource utilization.

The result is a more efficient, cost-effective, and reliable service experience for customers. With predictive maintenance, vehicle repair centers can enhance their operational efficiency, improve safety, and extend the lifespan of critical equipment, ultimately contributing to better overall business performance.

Optimizing Parts Procurement Strategies

AI tools for inventory management in vehicle repair centers can significantly optimize parts procurement strategies, ensuring that the right parts are available at the right time. These advanced systems leverage machine learning algorithms to predict demand patterns based on historical data, reducing overstock and minimizing stockouts. By integrating AI into inventory management, repair centers can streamline their purchasing processes, negotiate better prices with suppliers, and enhance overall operational efficiency.

Moreover, AI enables real-time tracking of parts inventory, allowing managers to make informed decisions about reordering and asset allocation. This not only cuts down on manual effort but also improves accuracy in parts identification and availability. As a result, vehicle repair centers can offer faster turnaround times for service and maintenance jobs, ultimately enhancing customer satisfaction and loyalty.

By leveraging AI tools for inventory management, predictive maintenance, and optimized parts procurement, vehicle repair centers can significantly enhance operational efficiency. Streamlining these processes reduces downtime, cuts costs, and improves overall productivity. As the digital era advances, embracing AI in vehicle repair offers a competitive edge, ensuring these centers stay vibrant and responsive to evolving industry demands.