AI systems for enhancing truck shop management revolutionize inventory control through accurate demand prediction and automation, minimize downtime with predictive maintenance, optimize scheduling and resource allocation based on historical data and driving patterns, streamline diagnostics using machine learning algorithms for computer vision and natural language processing, reduce manual labor, errors, and diagnostic times, continuously improving accuracy and efficiency in truck repair operations.

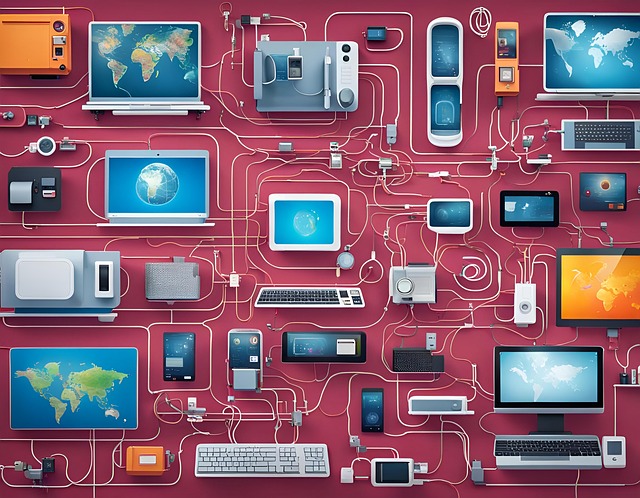

In today’s competitive trucking industry, efficient and proactive maintenance is key to minimizing downtime and maximizing profits. AI innovation strategies are revolutionizing truck repair operations, offering unprecedented efficiency gains in parts inventory management, predictive maintenance, and diagnostics. By integrating AI systems into truck shop management, businesses can streamline processes, reduce costs, and enhance overall fleet performance. This article explores these cutting-edge approaches, highlighting the transformative potential of AI in the trucking sector.

- Integrating AI for Efficient Parts Inventory Management

- Predictive Maintenance: AI's Role in Reducing Downtime

- Streamlining Diagnostics: AI-Powered Truck Inspection

Integrating AI for Efficient Parts Inventory Management

Integrating AI into parts inventory management for truck repair operations offers significant advantages, revolutionizing how shops optimize their resources. AI systems can analyze historical data on spare parts usage, identifying trends and predicting future demand with remarkable accuracy. This predictive capability ensures that the right parts are available when needed, minimizing stockouts and reducing the risk of excess inventory.

By leveraging machine learning algorithms, these AI systems can automate the ordering process, placing prompts for replenishment before stock levels dip too low. Moreover, AI-driven inventory management can streamline shelf organization, recommending part placements for quicker access during repairs. This enhances overall shop efficiency, enabling mechanics to focus on critical tasks while ensuring that every tool and spare part is readily available.

Predictive Maintenance: AI's Role in Reducing Downtime

Artificial Intelligence (AI) is transforming truck repair operations, and one of its most significant contributions is in predictive maintenance. By leveraging machine learning algorithms, AI systems analyze vast amounts of data from sensors installed on trucks to predict potential breakdowns before they occur. This proactive approach reduces unexpected downtime, as mechanics can perform repairs based on the insights provided by AI rather than waiting for issues to arise.

Moreover, AI enhances truck shop management by optimizing scheduling and resource allocation. It can forecast maintenance needs based on historical data and driving patterns, allowing repair shops to prepare in advance. This efficiency not only cuts costs but also improves overall fleet performance, ensuring that trucks are back on the road promptly and safely.

Streamlining Diagnostics: AI-Powered Truck Inspection

AI has the potential to revolutionize truck repair operations by significantly streamlining diagnostics and inspection processes. With AI-powered systems, truck repair shops can enhance their efficiency and accuracy in identifying issues. These advanced systems use machine learning algorithms to analyze sensor data, images, and historical records, enabling faster and more precise troubleshooting. For instance, computer vision algorithms can inspect visual components like brakes or lighting systems, while natural language processing (NLP) can interpret maintenance logs and reports, providing valuable insights into recurring problems.

By implementing AI in truck inspection, repair shops can reduce manual labor-intensive tasks, minimize human errors, and shorten diagnostic times. This technology allows for a more systematic approach to maintenance, ensuring no stone is left unturned during the inspection process. Additionally, AI systems can learn from each case, continuously improving their diagnostic capabilities, and providing mechanics with valuable data-driven information to make informed decisions, ultimately enhancing overall truck shop management.

AI innovation strategies, such as efficient parts inventory management, predictive maintenance, and AI-powered diagnostics, are transforming truck repair operations. By leveraging these AI systems for enhancing truck shop management, businesses can significantly reduce downtime, optimize resource allocation, and improve overall operational efficiency. Embracing these technologies is not just a trend but a necessary step towards staying competitive in the modern transportation industry.